High Pressure Oxygen Sintering Furnace HSO

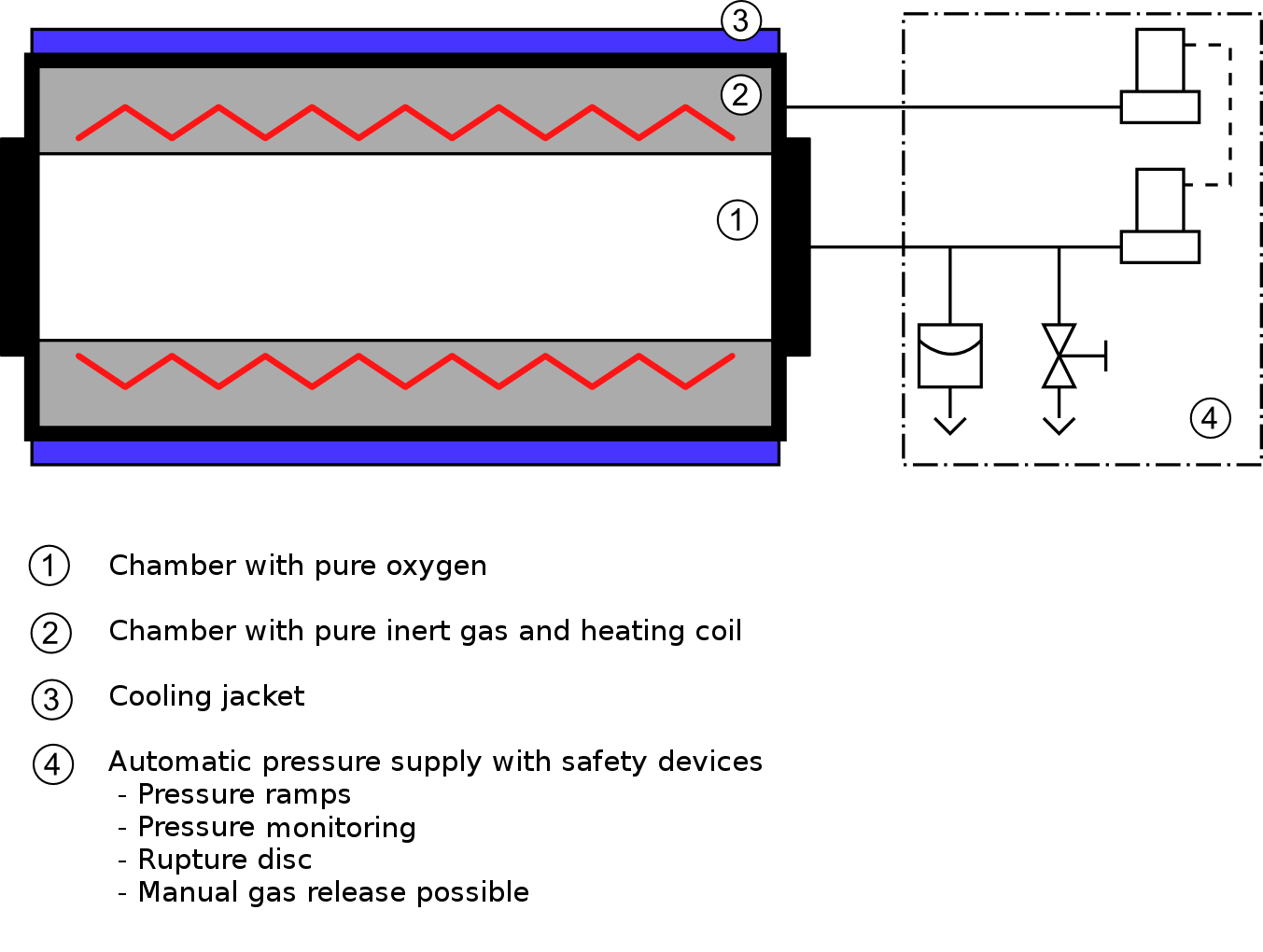

The high pressure oxygen sintering furnace HSO is unique device for high-pressure oxygen treatment of material rods under high temperatures up to 950 °C. Compared to conventional high pressure oxygen sintering furnaces, the main advantage of the HSO system is its reliable, safe and maintenance-free operation and a very high life span of all components. This is achieved by using of two gas-tightly separated, distinguished volumes inside a cold pressure tube. Thereby the heating elements are located inside an inert argon atmosphere, whereat the process chamber itself is filled with high-pressure oxygen. The pressure of each room is controlled automatically, separately and independently at all times of the heating or cooling procedure in order to guarantee stable and reproduceable process conditions.

The high pressure sintering furnace HSO completes the preprocessing setup for the high pressure crystal growth furnace HKZ. It covers the range from sintering oxidic rods for crystal growth to maintaining phases which are only stable at higher oxygen pressures. Besides that, it can be used for heat treatment of materials after crystal growth at high oxygen pressures up to 150 bar and at temperatures up to 950 °C. The furnace is equipped with a special non-reactive material tube offering an inner diameter of 25 mm and a heating zone of 200_mm with low temperature deviation. Greater tube dimensions are easily realizable on request. The clearly structured controls and display support the smooth handling of the machine. Several security mechanisms assure the correct operation of the furnace.

Technical details

Atmosphere

• Process chamber gas: oxygen

• Many other gases possible on request

• Heating elements chamber gas: argon (other inert gases possible on request, e.g. He, N2 etc.)

• Pressure: 1 to 150 bar

• Automatized pressure control while heating and cooling

Heating

• Specialized resistive heating elements

• Long life span due to protective environment

• Maintenance-free operation

• Maximum temperature: 950 °C, higher temperatures possible on request

Process chamber

• Dimensions: diameter 25 mm, heating zone length 200 mm

• Chamber material: non-reactive material withstanding high-pressure oxygen under high temperatures

• Precise thermocouple element for permanent temperature monitoring

Outer pressure tube

• Water-cooled metal casing

• No material fatigue due to low temperatures and non-reactive environments

Process control

• Build-in computer unit for all controlling purposes

• All system parameters are controllable and adjustable via a comfortable GUI on a build-in touchscreen

• Fully automatic or manual operation

• Power ramp functions with several temperature steps and heating/cooling rates adjustable

• Pressure pump functions with several pressure steps and rates adjustable

• Permanent data logging function

Required laboratory connections

• 160 bar oxygen and argon gas supply with constant pressure rate

• Energy supply: AC single phase 220-240_V

• Cooling water with approx. 20°C, pressure up to 3 bar, min. 4 liter/min, 4000 W cooling power

Furnace dimensions

• Tabletop device

• 57 cm x 69 cm x 52 cm (W x D x H)

• Weight: approx. 80 kg