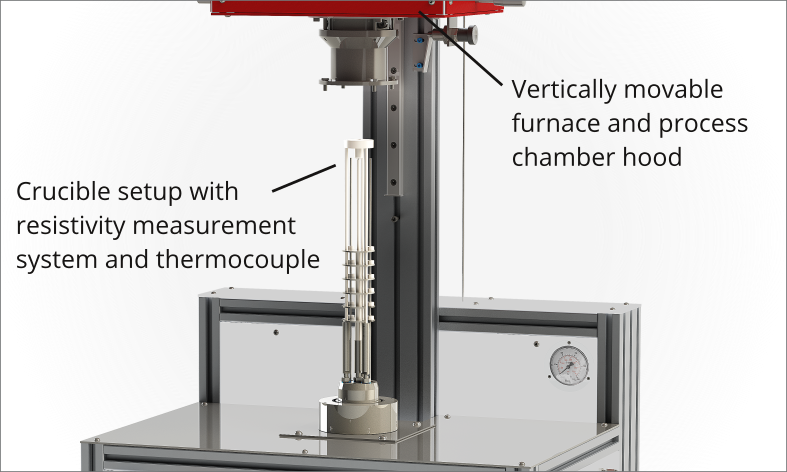

Feedback Furnace for flux crystal growth

To run the furnace, a standard computer screen, a mouse and a keyboard are needed. A vacuum pump can be connected to the flange at the right side of the furnace. Inert gases are let in through a screwed hose connection on the right side if the casting.

Technical details

- Max. temperature: 1300 °C

- Max. crucible dimensions: d = 25 mm, h = 50 mm

- Precise sample temperature monitoring by lock-in amplified resistivity measurements AND thermocouples

- Automatic detection of temperature anomalies down to 10-4 abs(T)

- Fully computer-controlled and automatable via GUI or python scripts

- Vacuum and gas connections

- Comfortable crucible installation due to a vertically movable furnace hood

Related publications

Joint publication with Augsburg University dealing with the feedback method:

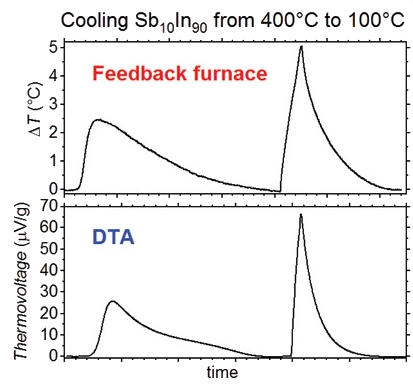

"In-situ detection of nucleation in high temperature solutions" 2019 by Andreas G. F. Schneider, Paul Sass, Robert Schöndube, Anton Jesche; Crystal Research and Technology 1900109

https://doi.org/10.1002/crat.201900109

In the Crystal Research and Technology invited paper we describe some details and first results of the feedback method, a novel in situ phase transition detection method and its implementation in a crystal growth setup for solution growth in controlled atmospheres. We are especially happy to see that the prototype of our Feedback Furnace is capable to reproduce DTA and DTS measurements while being a full-featured crystal growth equipment with automatic software-driven temperature control. The state of a sample is determined not by the nominal temperature in the process chamber, but by the onset or absence of characteristic signatures directly originating in the crystallization processes of the sample material. The in situ detection of phase transformations in the Feedback Furnace established a method and that offers a considerable increase in efficiency and accuracy for various solution growth processes. The Feedback Furnace is currently available for 1300 °C, other temperature ranges are possible on request.