Design and Development of a Liquid Helium Pump

The development of a new liquid helium pump was performed during a joint R&D project between ScIDre, the Bitzer-Chair of Refrigeration, Cryogenics and Compressor Technology of the TU Dresden and the Leibniz Institute for Solid State and Materials Research Dresden (IFW Dresden). The project was financially supported by the program Zentrales Innovationsprogramm Mittelstand (ZIM) of the Federal Ministry for Economic Affairs.

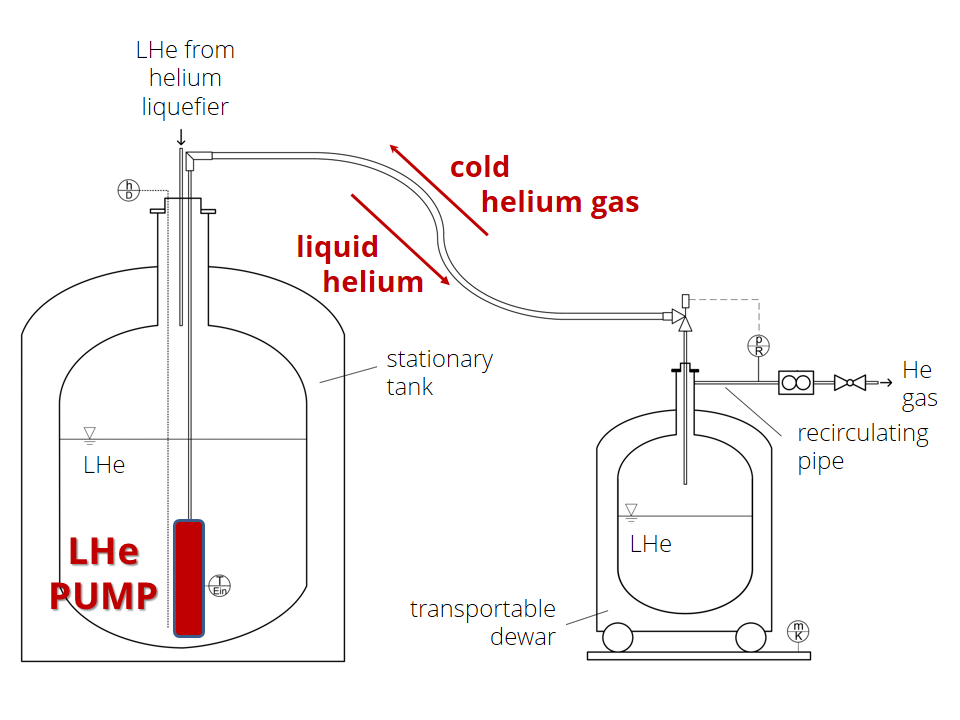

We designed and build a pump which is capable of transferring liquid helium (LHe) under ambient pressure conditions, e. g. from a stationary storage vessel into a mobile dewar at a LHe decant station. Conventionally, the most common LHe filling process uses a slight overpressure in order to transfer LHe into mobile dewars. Due to the partial evaporation of LHe transfer losses of up to 20 % occur. Thus generated helium gas has to be reliquefied, demanding a huge amount of electrical energy. Pumping LHe under ambient pressure diminishes these evaporation losses considerably. Another benefit of a LHe pump is its high transfer rate compared to a pressure-induced filling, which is often the bottleneck of the whole LHe supply.

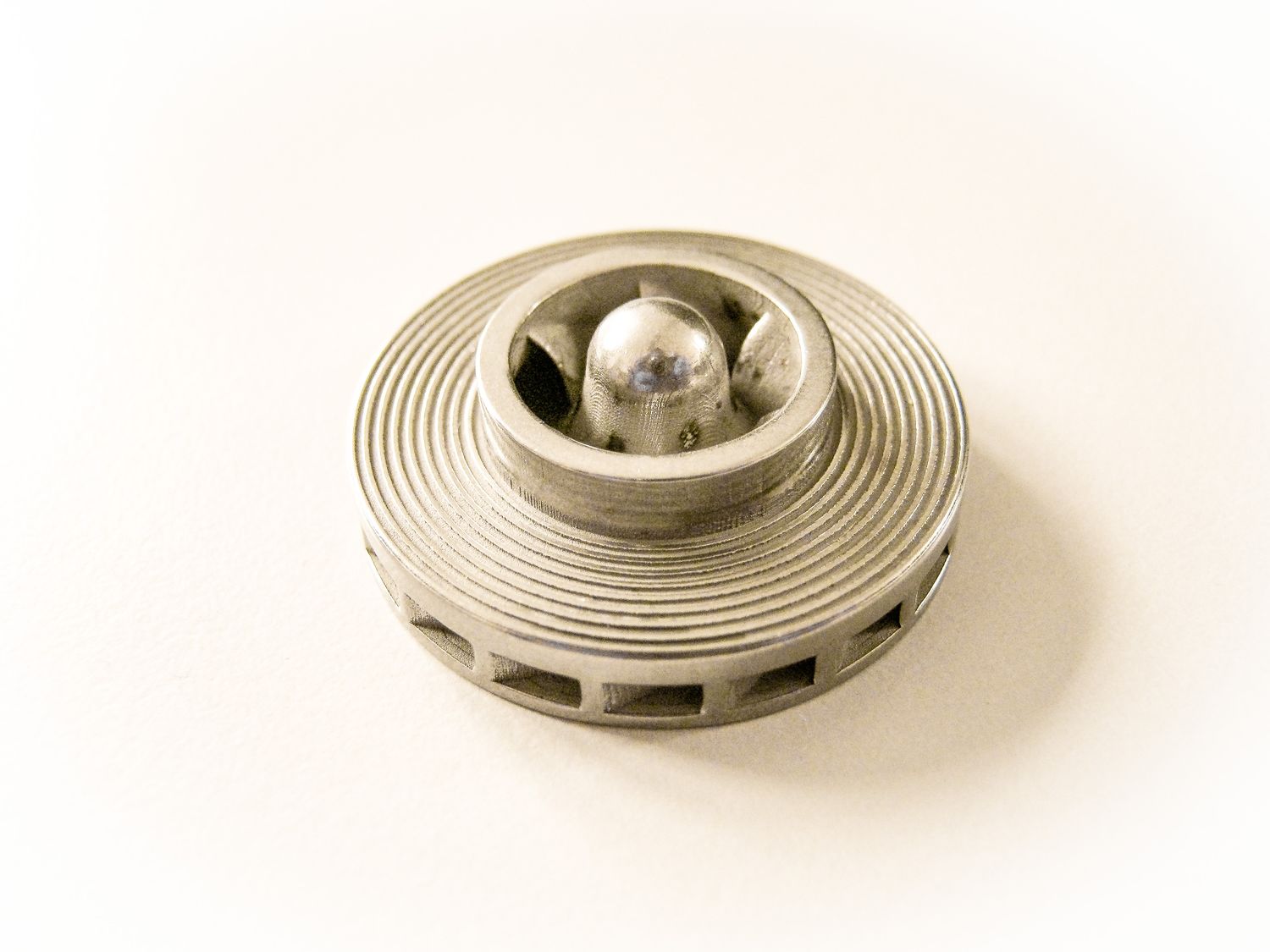

We use frictionless superconducting magnetic bearings which enable highest rotational speed and self-stabilizing, stiff positioning by superconducting magnetic levitation without heat dissipation. In order to maximize the pump efficiency, we performed extensive hydrodynamic calculations to develop optimized pump wheel and flow channel geometries. State-of-the-art sensor and controlling technologies ensure stable and efficient operation of the pump.

Inspiration for our project was taken from the LHe pump which was designed in the 1980s at the Walther-Meissner-Institute in Garching. Although containing many ingenious details, this pump never achieved widespread distribution due to its costly components and partly outdated technology. We created a worthy successor to this pioneering device.

The new LHe pump is now under testing and optimization process and will become available approximately early 2021. If you would like to have more information about any particular pump specifications, please contact us.