Laser-heated high-pressure floating zone furnace LKZ

The main part of our laser-heated floating zone crystal growth furnace LKZ are five 300 W diode lasers with wavelength of 980 nm. The rectangular geometry and size of the laser beams which impact the sample can be changed in a wide range in order to adapt to different sample materials and rod diameters. Beside the configurable laser heating system, one of the most striking features of our LKZ furnace is the possibility to perform laser-heated FZ crystal growths at high gas pressure of up to 300 bar. There are LKZ versions with 10 bar, 50 bar, 150 bar and 300 bar max. pressure available. The composition and pressure of the process atmosphere can be adjusted and controlled precisely with independent mass flow controllers for each gas and an easily automatable pressure regulator. This worldwide unique set-up allows the user to control the elements diffusion between melt and atmosphere to a certain grade and to manage the growth of materials, which are difficult or impossible to produce at low gas pressures due to the higher volatility of their elements or a meta-stable nature of the desired phase. Our patented laser-based afterheater system provides unparalleled flexibility for conducting additional thermal treatments on samples. The vacuum turbo pump is connected directly to the process chamber using short and wide-diameter pipes. This ensures good vacuum inside the process chamber, even below 10-5 mbar is possible. A lot of processes require an inert atmosphere with a low partial pressure of oxygen in order to perform ultra-clean growths. Our optional gas cleaning system removes oxygen traces out of argon reliably down to 10-12 ppm residual O2 concentration. Furthermore, the temperature of the floating zone as well as of the feed and crystal rods can be measured with high-quality bi-color pyrometer. All furnaces are equipped with precise linear and rotation feed through systems for synchronous or independent rotations with up to 50 rpm and linear pullings with rates starting from 0.1 or even 0.01 mm/h. A fast gear is implemented for rod set-up. High-pressure drives are magnetically coupled and completely capsuled without pressurized bearings. The entire set of experimental parameters such as laser power, linear and rotational movements of the pulling drives, mass flow and gas pressure are controlled by a programmable logic controller, PLC. A comfortable software application displayed and intuitively operated via touch screens combines all relevant system information and process adjustments in one graphical user interface unit. An important characteristic is the easily expandable modular design of the LKZ system, which allows add-ons and upgrades in an easy and cost-efficient way.

Laser heating

- Standard configuration: 5 x 300 W (total 1.5 kW) diode lasers for homogeneous radial power distribution

- Laser wavelength 980 nm

- Laser beam geometry: rectangular beam profile with 4 x 4 and 4 x 8 mm (other beam sizes and geometries available on request)

- Step-less power control, melting temperatures between 300 °C and 3000 °C (material dependent)

- High power uniformity within the laser beam spot due to optimized optical components

Atmosphere

- Argon and oxygen (pure and in any mixture)

- Many other gases also possible

- Gas pressure inside the growth chamber: 10-5 mbar to 300 bar

- manually controlled gas flow 0.1 to 1 l/min

- Each gas adjustable individually and independently

Pulling drives

- Precise linear and rotation feed through systems

- Pulling rate: 0.1 mm/h to 200 mm/h

- Fast gear mode

- Pulling length (max. crystal length): 100 mm (150 mm on request)

- Rotation rate: 0 to 70 rpm

Process control

- High-resolution CCD camera with HDR image optimization

- 360° image stacking system with 3 or 5 circular arranged cameras available

- Precise two-color pyrometer for real time temperature measurement

- Monitoring software: visual control, video recordings, snapshots and length measurements during the process

- Several advanced power ramp and travelling ramp functions adaptable

- Comfortable GUI for all PLC-based adjustments

Required lab connections

- Gas supply with 12 bar pressure

- Exhaust air system

- Energy supply

Furnace dimensions

- Height: 3020 mm, width: 1630 mm, depth: 800 mm

- All components are integrated into the housing (electronics, laser power supply, gas management)

- Modular housing in the 4-laser setup available to meet space requirement for beamline experiments

Figure above: Front view of the modular 5 x 300 W diode laser-heated FZ furnace with rectangular beam profile and advanced process gas management up to 300 bar

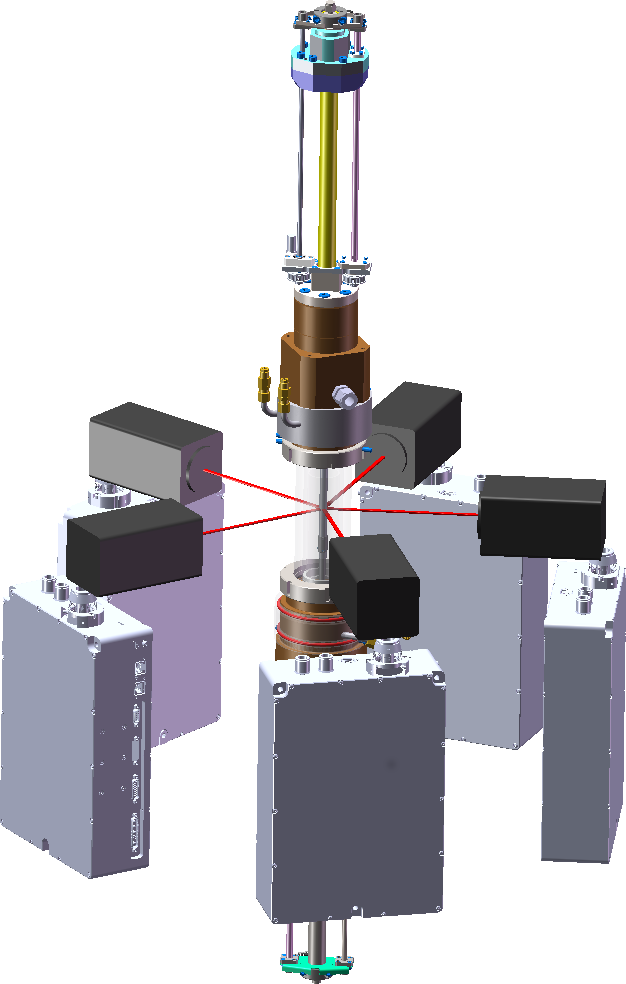

Figure above: Front view of the modular 5 x 300 W diode laser-heated FZ furnace with rectangular beam profile and advanced process gas management up to 300 bar Figure above: Visualization of the LFZ process chamber room with 5 laser beams

Figure above: Visualization of the LFZ process chamber room with 5 laser beams Figure above: LKZ laser spots feature a rectangular spot geometry with highly homogeneous power distribution, selectable between 4 x 4 and 4 x 8 mm

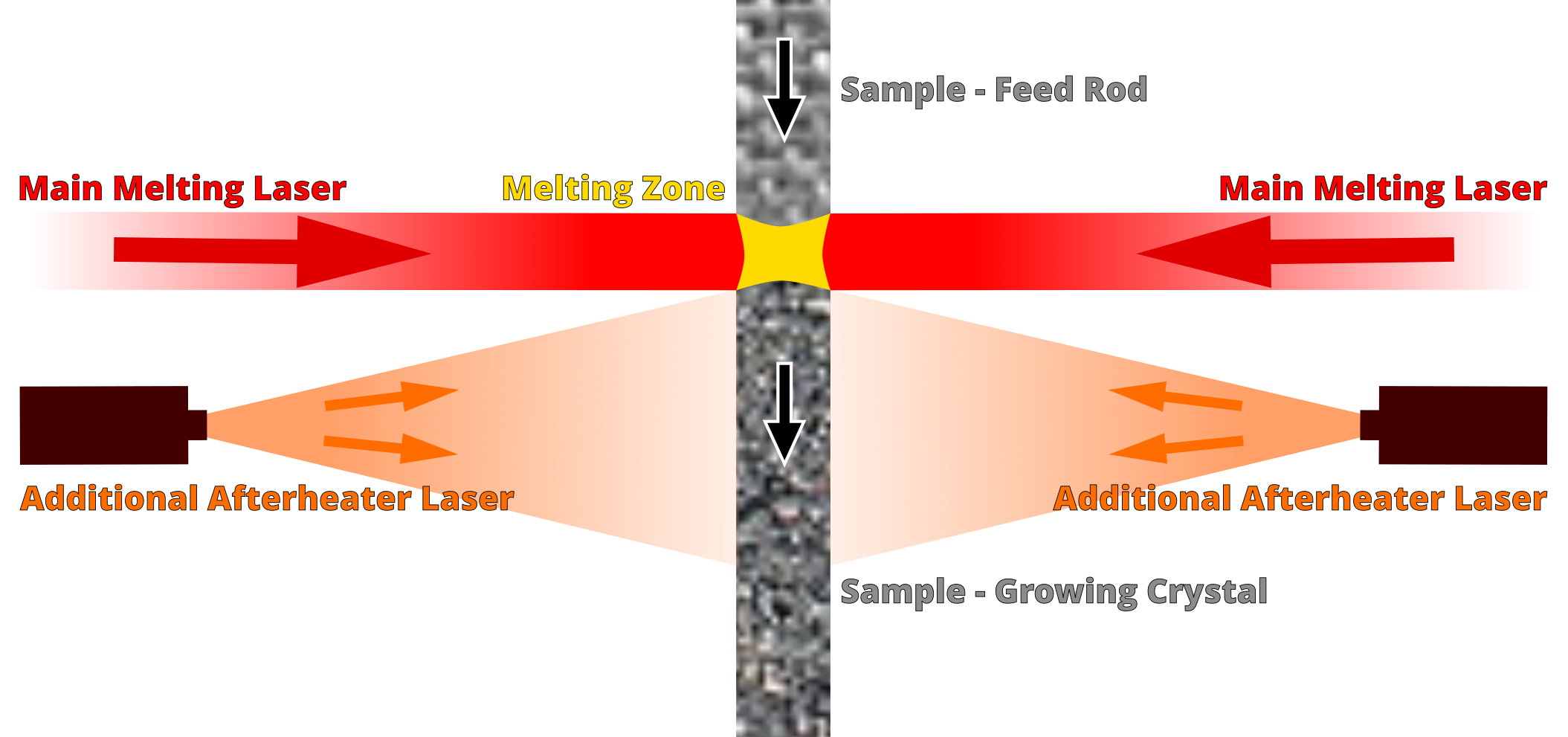

Figure above: LKZ laser spots feature a rectangular spot geometry with highly homogeneous power distribution, selectable between 4 x 4 and 4 x 8 mm Figure above: The patented laser-based afterheater system can be applied for the additional thermal treatment of sample after (or before) crystal growth

Figure above: The patented laser-based afterheater system can be applied for the additional thermal treatment of sample after (or before) crystal growth